Mixing and Blending

Alphie 10 Liter 3D Powder Mixer

The Alphie 10 liter mixer is ideal for homogeneous mixing of powder – be it with different bulk density or different proportion of mixing or different shape and particle size. The best part is, separate and detachable mixing drum / container / bin is loaded inside the mixing cage, meaning no cross contamination and exposure to work environment.

It is perfect for use in R & D laboratories, educational institutes, small batch production industry, food / nutrition, pharmaceuticals, metal powder, resin and plastic powder, Nano powder, IOL Polishing, Diamond tool powder, bakery, spices, concentrates and many more applications.

Alphie 2 Liter Manual 3D Tumble Mixer

The motion of Alphie mixer is based on the kinematic inversion principle. The unusual, three-dimensional mixing motion quickly and efficiently produces a homogeneous substance regardless of specific weight of the substances being mixed. This makes it an ideal powder blender or liquid mixer.

Manual Alphie Mixer brings same technology power – generating rhythmic and pulsating movement controlled naturally by hand. Added with the mobility!

Typical applications

It is ideal for use in R & D laboratories, educational institutes, small batch production industry, food/nutrition, pharmaceuticals, metal powder, resin and plastic powder, restaurants, bars and kitchens, bakery, spices, concentrates and many more applications

Alphie 20 Liter 3D Powder Mixer

Alphie 3D mixers are ideal for homogeneous mixing of powder – be it with different bulk density or different proportion of mixing or different shape and particle size. The best part is, separate and detachable mixing drums / containers / bins are loaded inside the mixing cage, meaning no cross contamination and exposure to work environment.

Our 20 liter model uses identical principals as the smaller R & D scale models. It means the machine shall rotate in similar three dimensional motion and shall yield same results.

Typical applications

It is ideal for use in medium to large batch production industries like food / nutrition, pharmaceuticals, metal powder, resin and plastic powder, bakery, spices, concentrates, nuclear fuel and many more applications.

Please see this video showing how to use smaller containers down to 2.0 liters.

Alphie 3- 2.5 Liter 3D Powder Mixer

Alphie mixer are ideal for homogeneous mixing of powder – be it with different bulk density or different proportion of mixing or different shape and particle size. The best part is, separate and detachable mixing drum / container / bin is loaded inside the mixing cage, meaning no cross contamination and exposure to work environment.

Alphie 35 Liter 3D Powder Mixer

Alphie 3D mixers are ideal for homogeneous mixing of powder – be it with different bulk density or different proportion of mixing or different shape and particle size. The best part is, separate and detachable mixing drums / containers / bins are loaded inside the mixing cage, meaning no cross contamination and exposure to work environment.

Our 35 liter model uses identical principals as the smaller R & D scale models. It means the machine shall rotate in similar three dimensional motion and shall yield same results.

Typical applications

It is ideal for use in medium to large batch production industries like food / nutrition, pharmaceuticals, metal powder, resin and plastic powder, bakery, spices, concentrates, nuclear fuel and many more applications.

Alphie 50 Liter 3D Powder Mixer

Alphie 3D mixers are ideal for homogeneous mixing of powder – be it with different bulk density or different proportion of mixing or different shape and particle size. The best part is, separate and detachable mixing drums / containers / bins are loaded inside the mixing cage, meaning no cross contamination and exposure to work environment.

Our 50 liter model uses identical principals as the smaller R & D scale models. It means the machine shall rotate in similar three dimensional motion and shall yield same results.

Typical applications

It is ideal for use in medium to large batch production industries like food / nutrition, pharmaceuticals, metal powder, resin and plastic powder, bakery, spices, concentrates, nuclear fuel and many more applications.

SK-10000T/TV Planetary Centrifugal Mixer

Model equipped for both high speed revolution and a wide radius gyration, supporting for the production of high quality materials.

The timing by which the revolving speed of rotation increases is controlled to improve the mixing rate of powders and liquids and sustains the generation of lumps.

2 cups x 10 Liters

SK-1100T Planetary Centrifugal Mixer

Model equipped for both high speed revolution and a wide radius gyration, supporting for the production of high quality materials.

The timing by which the revolving speed of rotation increases is controlled to improve the mixing rate of powders and liquids and sustains the generation of lumps.

1100ml × 2 cups

SK-1100TVII / SK-1100TVSII Planetary Centrifugal Mixer with Vacuum

SK-1100TVII / SK-1100TVSII Planetary Centrifugal Mixer with Vacuum

A model with a vacuum reduced pressure function suited for medium-scale production.

The individual revolution and rotation speed control system and wide radius gyration generate centrifugal force even at low revolving speeds, sustaining material of thermal elevation and composition change.

1100ml × 2 cups

SK-2000T Planetary Centrifugal Mixer

Features

2000ml × 2 cups (2kg)

SK-300SVII Planetary Centrifugal Mixer with Vacuum

A compact, vacuum function, 1-cup, reasonable model with a simple mechanism.

With low revolving speed of 400G centrifugal force, it enables to control thermal elevation of materials.

300ml × 1 cup

SK-300TVSII 600ml Planetary Centrifugal Mixer with Vacuum

SK-300TVSII 600ml Planetary Centrifugal Mixer with Vacuum

A high function model with a vacuum reduced pressure function.

The individual revolution and rotation speed control system and the shifted cup tray enhance mixing performance and provide effective degassing.

300ml × 2 cups

SK-350TII Planetary Centrifugal Mixer

90 different revolution-rotation speed patterns are available by varying the ratio of revolution and rotation.

A high function model for covering from research and development to small-scale production.

400 ml × 2 cups Compatible with various types of syringe

SK-350TV / SK-350TVS Planetary Centrifugal Mixer with Vacuum

SK-350TV / SK-350TVS Planetary Centrifugal Mixer with Vacuum

Greatly improved mixing performance with the same features as existing models!

A new advanced function model equipped with the individual revolution and rotation speed control system!!

400ml × 2 cups

SK-4000T/TV Planetary Centrifugal Mixer

Model equipped for both high speed revolution and a wide radius gyration, supporting for the production of high quality materials.

The timing by which the revolving speed of rotation increases is controlled to improve the mixing rate of powders and liquids and sustains the generation of lumps.

2 cups x 4 Liters

SK-MP12 Planetary Centrifugal Mixer for Microplate

Uniform mixing of samples in the microplate and ultrafine air bubble elimination with high speed processing.

This contributes to improved measurement result reliability.

Click here for information video.

Grinding and Milling

-

Grinding & Milling, Jet Mills

Jet Mills

A jet mill grinds materials by using a high speed jet of compressed air or inert gas to impact particles into each other. Jet mills can be designed to output particles below a certain size, while continue milling particles above that size, resulting in a narrow size distribution of the resulting product. Particles leaving the mill can be separated from the gas stream by cyclonic separation.

SKU: n/a -

Grinding & Milling, Jaw Crushers

BB 200 Jaw Crusher

The Jaw Crusher BB 200 is used for the rapid, effective crushing and pre-crushing of medium-hard, hard, brittle and tough materials. Its variety of materials offered, including heavy-metal free steel, its efficiency and safety makes it ideal for sample preparation in laboratories and industrial plants.

For small amounts of sample the BB 200 can be used batch-wise; for larger amounts it can be operated continuously. Control of the gap width and zero point adjustment allow for reproducible results. The Belleville spring washer protects the Jaw Crusher from overloads and in conjunction with maintenance- and lubricant-free sliding bearings guarantees a long service life.

SKU: n/a -

Grinding & Milling, Mixer Mills

MM 500 Mixer Mill

The mixer mill MM 500 is a compact, versatile bench-top unit which has been developed specially for dry, wet and cryogenic grinding of up to 2 x 45 ml sample material within seconds.

With a maximum frequency of 35 Hz, it generates enough energy to produce particles in the nanometer range. The robust high-performance drive makes the mill suitable for long-term grinding processes up to 99 hours. Hence, the MM 500 is the first mixer mill in the market to provide a real alternative to grinding in a planetary ball mill – with more comfortable handling and less warming effects.

SKU: n/a -

Grinding & Milling, Jaw Crushers

BB 300 Jaw Crusher

The Jaw Crusher BB 300 is used for the rapid, effective crushing and pre-crushing of medium-hard, hard, brittle and tough materials. Its variety of materials offered, including heavy-metal free steel and its efficiency and safety makes the BB 300 ideal for sample preparation in laboratories and industrial plants.

For small amounts of sample the Jaw Crusher BB 300 can be used batch-wise; for larger amounts it can be operated continuously. Control of the gap width and zero point adjustment allow for reproducible results. The Belleville spring washer protects the unit from overloads and in conjunction with the central lubrication guarantees a long service life.

SKU: n/a -

-

Disc Mills, Grinding & Milling

RS 300 Vibratory Disc Mill

The Vibratory Disc Mill RS 300 is suitable for the extremely quick, loss-free and reproducible grinding of medium-hard, brittle and fibrous materials to analytical fineness. It is possible to process 1, 2, 3 or 4 samples simultaneously. Thanks to the robust universal drive shaft, which sets the grinding jar into a 3-D motion, this mill accepts grinding set weights of up to 30 kg. The closed grinding system guarantees complete processing of the sample.

Just like the RS 200, the RS 300 with its robust design has proven to be ideally suitable for applications in geology, mineralogy, metallurgy, as well as in the building materials sector (cement) and in power plants.

Due to the high end fineness and speed, the Vibratory Disc Mills are the perfect choice when it comes to preparing samples for spectral analysis.

SKU: n/a

Cutting Mills

-

Cutting Mills, Grinding & Milling

SM 100 Cutting Mill

Cutting mills are suitable for the grinding of soft, medium-hard, elastic, fibrous, and heterogeneous mixes of products.

The SM 100 is the budget-priced basic model among the cutting mills. With its strong 1.5 kW drive and 1,500 rpm rotor speed the mill is particularly suitable for routine applications. Cleaning is made particularly easy.

In combination with the wide choice of bottom sieves, hoppers and collecting vessels, the mill can be easily adapted to varying application requirements. The SM 100 can be bench-mounted; alternatively a convenient base frame on wheels is available.

SKU: n/a -

Cutting Mills, Grinding & Milling

SM 200 Cutting Mill

Cutting mills are suitable for the grinding of soft, medium-hard, elastic, fibrous, and heterogeneous mixes of products. The new cutting mill SM 200 is a powerful and easy-to-operate instrument for efficient primary and fine size reduction. Cleaning is made particularly easy.

Within the group of the cutting mills, it is the universal standard model which covers a vast range of applications with its strong 2.2 kW drive and 1,500 rpm rotor speed. When operated with the optional cyclone-suction-combination, the SM 200 is also suitable for grinding light sample materials or smaller quantities. In combination with the wide choice of bottom sieves, hoppers and collecting vessels, the mill can be easily adapted to varying application requirements.

SKU: n/a -

Cutting Mills, Grinding & Milling

SM 300 Cutting Mill

Cutting mills are suitable for the grinding of soft, medium-hard, tough, elastic, fibrous, and heterogeneous mixes of products. The new Cutting Mill SM 300 excels especially in the tough jobs where other cutting mills fail.

The high torque of the new 3 kW drive with RES technology (additional flywheel mass) allows for an exceptionally effective preliminary size reduction of heterogeneous mixtures, such as waste or electronic components. Analytical fineness is often achieved in one working run.

The cutting mill is used successfully for a great variety of materials. The sample is only moderately warmed up during the grinding process so that the mill is perfectly suitable for grinding temperature-sensitive materials. Another innovation is the wide, freely selectable speed range from 100 to 3,000 min-1.

When operated with the optional cyclone-suction-combination, the SM 300 is also suitable for grinding light sample materials or smaller quantities. In combination with the wide choice of bottom sieves, hoppers and collecting vessels, the mill can be easily adapted to varying application requirements.

SKU: n/a -

Cutting Mills, Grinding & Milling

SM 400 Cutting Mill

Cutting mills are suitable for the grinding of soft, medium-hard, tough, elastic, fibrous, and heterogeneous mixes of products. The Cutting Mill SM 400 is ideally suited for pre-cutting of large sample pieces but, depending on the application, may also achieve the required fineness in one step.

The high torque of the new 3 kW drive allows for an exceptionally effective preliminary size reduction of heterogeneous mixtures, such as waste or electronic components.

The cutting mill is used successfully for a great variety of materials. The sample is only moderately warmed up during the grinding process so that the mill is perfectly suitable for grinding temperature-sensitive materials. Due to the large open surface of the 240 mm x 240 mm bottom sieve, it is possible to grind large sample quantities and to increase the throughput.

When operated with the optional cyclone-suction-combination, the SM 400 is also suitable for grinding light sample materials. In combination with the wide choice of bottom sieves, hoppers and collecting vessels, the mill can be easily adapted to varying application requirements.

SKU: n/a -

Cutting Mills, Grinding & Milling, Hammer Mills

Kinematica™ Polymix™ PX-MFC 90 D Hammer or Cutting Mill

Cutting Mills, Grinding & Milling, Hammer MillsKinematica™ Polymix™ PX-MFC 90 D Hammer or Cutting Mill

Analysis or quality control requires finely ground samples. Easy to change grinding attachments and sieves extend the range of any samples that can be processed. Simple handling, high user safety and efficient grinding results are just a few of the advantages of this mill.

SKU: n/a

Assisting

-

Assisting, Pellet Presses

PP 35 Pellet Press

Solid, high-quality pellets are an important precondition for reliable and meaningful XRF analysis. With the PP 35, RETSCH offers a pellet press which produces strong pellets with a smooth surface.

The PP 35 features an individual pressure force regulation in the range of 0 to 35 t. The PP 35 combines the advantage of a small bench top model with high press forces, which are built automatically in up to three steps, ensuring that even difficult materials are pressed perfectly.

SKU: n/a -

Assisting, Ultrasonic Baths

UR Ultrasonic Baths

The ultrasonic bath range UR includes three sizes for cleaning test sieves and grinding tools quickly and easily. UR 1 is for test sieves up to 203 mm dia., UR 2 for test sieves up to 450 mm dia., and the UR 3 for the simultaneous cleaning of up to 5 test sieves 200/203 mm dia. The gentle yet thorough cleaning of test sieves in an ultrasonic bath increases their working lives as damage which could occur during manual cleaning is avoided.

SKU: n/a -

Assisting, Vibratory Feeders

DR 100 Vibratory Feeder

The vibratory feeder DR 100 is used for the uniform, continuous feeding and conveyance of pourable bulk materials and fine powders. The DR 100 feeds mills, sample dividers, and particle measuring devices, and it is also suitable for other feeding tasks. Its performance, adaptability and compact design makes this device suitable for a great variety of applications. The DR 100 can also be driven and controlled externally via the built-in interface. Vibratory feeders guarantee reproducibly exact results and maximize the efficiency of downstream laboratory and testing devices.

SKU: n/a -

Assisting, Sample Splitters

RT 100 Sample Splitter

A faultless and comparable analysis is closely linked to an accurate sample handling. Only a sample representative of the initial material can provide meaningful analysis results. Sample splitters ensure the representativeness of a sample and thus the reproducibility of the analysis.

The RT 100 is equipped with a feed hopper with closed outlet. Thus, up to 30 l sample material may be evenly spread over the entire width of the hopper. The outlet is opened manually by moving a lever and the sample is splitted. The slots of the dividing head can be adjusted to a maximum width of 108 mm.

The sample splitters RT are ideal for the on-site reduction of sample material. They are easy to use, easy to clean and do not need an electrical power supply.

SKU: n/a -

Assisting, Pellet Presses

PP 25 Pellet Press

Solid, high-quality pellets are an important precondition for reliable and meaningful XRF analysis. The PP 25 is a compact benchtop unit with particularly simple and safe operation. With a pressure force of 25 t it is ideally suited for the preparation of solid samples for XRF analysis. The pellets produced are of high quality and are characterized by their high degree of stability. The piston pressure can be read off from the clearly visible manometer scale. The dies for the Pellet Press PP 25 are available in several diameters and can be evacuated completely.

SKU: n/a

Sieve Shakers and Test Sieves

View All Recommendations-

Test Sieves

200 / 305 / 400 mm Perforated Plate Sieves

The well-proven RETSCH perforated plate sieves consist of a solid stainless steel sieve frame of high stability for reliable sieving results.

The sieves can be easily combined with all other sieve brands. Each sieve that leaves our company comes with a test report.

SKU: n/a -

Test Sieves

200/203 mm Mesh Sieves

The well-proven RETSCH sieves consist of a solid stainless steel sieve frame of high stability for reliable sieving results. Paying close attention to mesh-specific requirements, the sieve fabric is precisely joined into the frame and tautened. The individual laser engraving of each RETSCH test sieve provides a clear and accurate labeling with full traceability.

The sieves can be easily combined with all other sieve brands. Each sieve that leaves the company comes with a test report or, at your request, with a special inspection certificate in conformity with national and international standards (PDF). RETSCH calibration certificates confirm a great number of precision measurements, thus ensuring an even higher statistical reliability for your quality control.

RETSCH test sieves are available in many sizes and varieties, primarily in the four frame sizes most widely used in laboratory analytics:

- 200 x 50 mm, 200 x 25 mm

- 8“x 2“ (203 x 50 mm), 8“x 1“ (203 x 25 mm)

SKU: n/a -

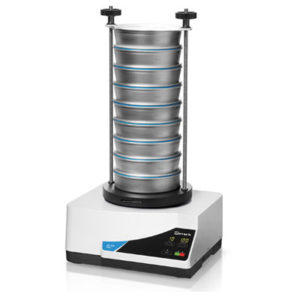

Sieve Shakers

AS 200 Basic Sieve Shaker

The vibratory sieve shakers of the series AS 200 are used in research & development, quality control of raw materials, interim and finished products as well as in production monitoring. The controllable electromagnetic drive offers an optimal adaption for every product. Sharp fractions are obtained even after short sieving times.

The AS 200 basic sieve shaker is the economical alternative of the series with familiar quality and reliability. It features digital setting and display of performance and time.

SKU: n/a -

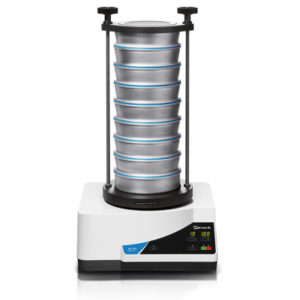

Sieve Shakers

AS 200 Control Sieve Shaker

The analytical sieve shakers of the series AS 200 are used in research & development, quality control of raw materials, interim and finished products as well as in production monitoring. The controllable electromagnetic drive offers an optimal adaption for every product. Sharp fractions are obtained even after very short sieving times.

With its all-digital controls, up to 99 sieving programs and calibration certificate the sieve shaker AS 200 control is indispensable for all users who attach importance to precision and operational convenience and need to comply with the guidelines of the ISO 9001.

SKU: n/a -

Sieve Shakers

AS 200 Digit Sieve Shaker

The analytical sieve shakers of the series AS 200 are used in research & development, quality control of raw materials, interim and finished products as well as in production monitoring. The controllable electromagnetic drive offers an optimal adaption for every product. Sharp fractions are obtained even after short sieving times.

The AS 200 digit cA sieve shaker is recommended whenever controlled amplitude, digital display of vibration height and time and interval operation are required.

SKU: n/a -

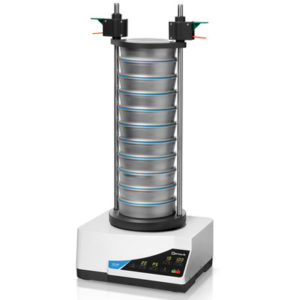

Sieve Shakers

AS 200 Jet Sieve Shaker

The new Air Jet Sieve AS 200 jet is particularly suitable for sieve cuts of powdered materials which require efficient dispersion and deagglomeration. The option to store up to 10 SOPs and the automatic vacuum regulator (accessory) guarantees reproducible and meaningful results.

Innovative features such as the Open Mesh function, the selection of the nozzle speed as well as optional use of standard 2″ high test sieves perfects the new air jet technology.

SKU: n/a -

Sieve Shakers

AS 200 Tap Sieve Shaker

The analytical sieve shaker AS 200 tap is used in research & development, quality control of raw materials, interim and finished products as well as in production monitoring. Its tapping motion supports the sieve analysis of certain products such as activated carbon, abrasives, metal powder, spices and diamonds, as specified in the corresponding standards.

SKU: n/a -

Sieve Shakers

AS 300 Control Sieve Shaker

The analytical sieve shaker AS 300 control is used in research & development, quality control of raw materials, interim and finished products as well as in production monitoring. The controllable electromagnetic drive offers an optimal adaption for every product. Sharp fractions are obtained even after short sieving times.

The AS 300 control is particularly designed for test sieves with a diameter of 305 mm (12″). Compared to sieves with a diameter of 200 mm, a 2.25 times higher sieving surface is available. Therefore, the average sieving times can be greatly reduced with the AS 300 control. With its all-digital controls and calibration certificate the sieve shaker AS 300 control is indispensable for all users who attach importance to precision and operational convenience and need to comply with the guidelines of the ISO 9001.

SKU: n/a -

Sieve Shakers

AS 400 Control Sieve Shaker

The analytical sieve shaker AS 400 control is used in research & development, quality control of raw materials, interim and finished products as well as in production monitoring.

The AS 400 control is used for the sieving of dry goods with test sieves of a diameter up to 400 mm. In this, the uniform, horizontal circular motion ensures exact separation of fine and coarse-grained products.

With its all-digital controls and calibration certificate the AS 400 control is indispensable for all users who attach importance to precision and operational convenience and need to comply with the guidelines of the ISO 9001.

SKU: n/a -

Sieve Shakers

AS 450 Basic Sieve Shaker

The AS 450 basic, is a budget-priced alternative to the AS 450 control sieve shaker. The new sieve shaker covers a size range from 25 μm to 125 mm and accepts loads of up to 15 kg. Time and amplitude are digitally set, a memory function allows storage of one program. The AS 450 basic is suitable for dry and wet sieving. It is the economic solution for customers who need to sieve larger quantities of dry material with reliable results.

SKU: n/a -

Sieve Shakers

AS 450 Control Sieve Shaker

The analytical sieve shaker AS 450 control is used in research & development, quality control of raw materials, interim and finished products as well as in production monitoring. The controllable electromagnetic drive offers an optimal adaption for every product. Sharp fractions are obtainable even after very short sieving times.

With the sieve shaker AS 450 control RETSCH have designed their first sieve shaker for 400 mm and 450 mm sieves which operates with a three-dimensional sieving motion. It can be used for dry and wet sieving. The optimized electromagnetic drive technology allows for an amplitude up to 2.2 mm even with maximum loads up to 25 kg. This makes the AS 450 superior to all other known sieve shakers based on conventional electromagnetic or imbalance drives.

SKU: n/a