Application Examples

Animal Feed, Bones, Chemical Products, Food, Hair, Oil Seeds, Paper, Plant Materials, Plastics…

Product Advantages

- Powerful cryogenic grinding by impact and friction, up to 30 Hz

- 3 different grinding modes (cryogenic, dry or wet at ambient temperature)

- Closed LN2-system (autofill) for enhanced safety, avoids any contact of the user with LN2

- Screw-top grinding jars for convenient, leak-proof operation

- Wide range of accessories including various LN2 feeding systems, jar and ball sizes, adapter racks, materials

- Low LN2-consumption

- Clearly structured user interface, memory for 9 SOPs

- Programmable cooling and grinding cycles (10 s to 99 min)

- Ceramic jar available

Function Principle

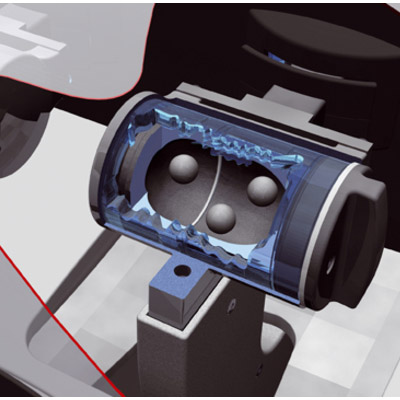

The grinding jar of the CryoMill performs radial oscillations in a horizontal position. The inertia of the grinding balls causes them to impact with high energy on the sample material at the rounded ends of the grinding jar and pulverize it.

The grinding jar is continually cooled with liquid nitrogen from the integrated cooling system before and during the grinding process.