Application Examples

bones, cereals, chemical products, coal, coffee beans, collagen, corn, dried fruit and vegetables, dried larvae, drugs, electronic components,bones, cereals, chemical products, coal, coffee beans, collagen, corn, dried fruit and vegetables, dried larvae, drugs, electronic components…

Product Advantages

- Powerdrive with optimally matched frequency converter and 3-phase motor

- gentle and very rapid size reduction by pre- and fine grinding in one run

- wide speed range

- patented cassette system for maximum sample recovery and easy cleaning

- easily exchangeable grinding and sieve inserts

- defined final fineness due to ring sieves with aperture sizes from 0.08 – 10 mm

- comfortable safety housing with automatic cover closure

- motor compartment and electronics protected against dust and material penetration

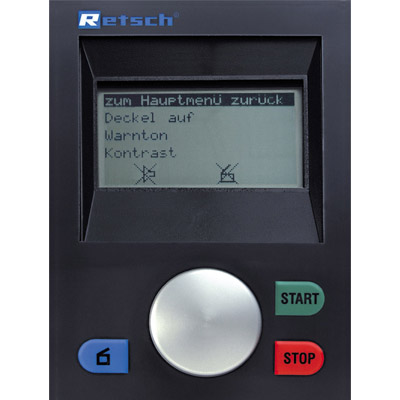

- comfortable parameter setting via display and ergonomic 1-button operation

- wide range of accessories including various collection and feeding systems, rotors and sieves

Function Principle

In the Ultra Centrifugal Mill ZM 200 size reduction takes place by impact and shearing effects between the rotor and the fixed ring sieve. The feed material passes through the hopper (with splash-back protection) onto the rotor. Centrifugal acceleration throws it outward with great energy and it is precrushed on impact with the wedge-shaped rotor teeth moving at a high speed. It is then finely ground between the rotor and the ring sieve.

This 2-step grinding ensures particularly gentle but fast processing. The feed material only remains in the grinding chamber for a very short time, which means that the characteristic features of the sample to be determined are not altered. The ground sample is collected in the collecting cassette surrounding the grinding chamber or in the downstream cyclone or paper filter bag.