Application Examples

Cereals, Corn, Feed Pellets, Forage, Pasta, Pharmaceutical Products, Soy, Rice, Tobacco, …

Product Advantages

- Ideal for grinding feeds, grains, forage and other similar products

- 3 controlled speeds

- Cyclone separator with 250 ml collecting bottle for quick extraction of sample

- No cross contamination thanks to easy cleaning

- Convenient operating panel

- Robust industrial motor 900 W with long lifetime

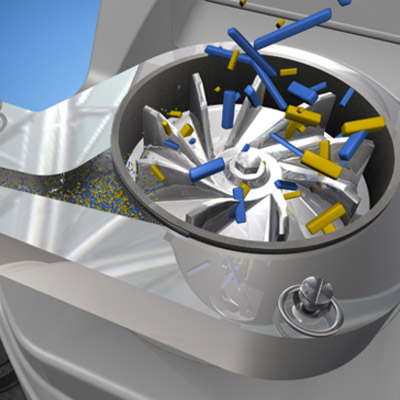

Function Principal

In the cyclone mill TWISTER size reduction is effected by impact and friction between the rotor and the friction surface of the fixed grinding ring. The feed material passes through the hopper (with splash-back protection) onto the rotor which is rotating with high speed and is thus submitted to preliminary size reduction. The sample is then thrown outwards by centrifugal acceleration and is pulverized between rotor and grinding ring. The 2-step grinding ensures particularly gentle but fast processing. The feed material only remains in the grinding chamber for a very short time. The integrated cyclone provides cooling of the sample and the grinding tools. This guarantees preservation of the sample properties to be determined. The ground material is separated in the cyclone and collected in a sample bottle.