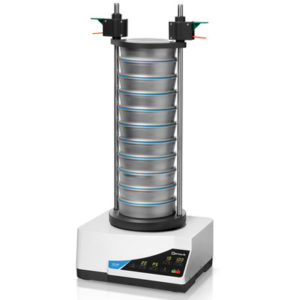

Application Examples

Cement, Cement Clinker, Ceramics, Coal, Coke, Concrete, Corundum, Electronic Components, Glass, Metal Oxides, Minerals, Ores, Plant Materials, Silicates, Slag, Soils…

Product Advantages

- Reproducible results and homogeneous samples thanks to universal drive shaft (3D vibration of grinding sets)

- Speed: 912 min-1

- Short grinding times

- Autoreverse function (left/right rotation)

- Programmable interval function (start/ stop automatic)

- Wide range of materials for contamination-free grinding

- Grinding jar volumes from 100 ml up to 2,000 ml

- Closed and noise-insulated grinding chamber

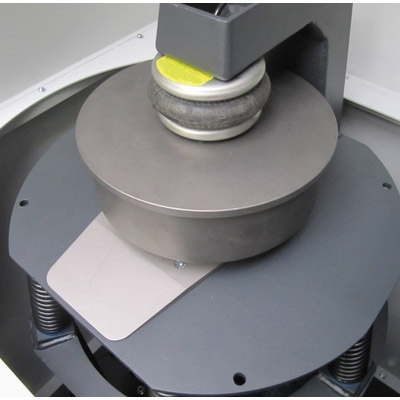

- Pneumatic grinding-jar clamping (with air-pressure) for convenient and safe handling

- Additional security feature: mill only starts if the pneumatic pressure is correct

- Optional Autolifter for ergonomic lifting of heavy grinding sets

Function Principle

The vibratory disc mill comminutes by impact and friction. The grinding set is firmly attached to the vibration plate with a pneumatic quick clamping device. The plate with the grinding set is subjected to 3-D vibrations.

The sample is crushed by extreme pressure, impact and friction generated by centrifugal forces acting on the grinding rings in the dish.The vibrations are produced by a frequency controlled 2.2 kW 3-phase motor.