Application Examples

Cement, Cement Clinker, Ceramics, Coal, Coke, Concrete, Corundum, Electronic Components, Glass, Metal Oxides, Minerals, Ores, Plant Materials, Silicates, Slag, Soils…

Product Advantages

- Reproducible results due to “Stabilized-Plane-Drive” (avoids tumbling of the grinding set)

- Variable speed 700 – 1,500 min-1

- Extremely short grinding time

- Agate and tungsten carbide recognition for automatic speed reduction

- 10 SOPs can be stored

- No sample loss thanks to optimum o-ring seal

- Wide range of materials for contamination free grinding

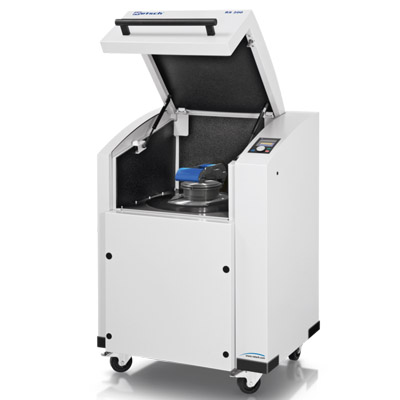

- Noise-insulated grinding chamber

- New quick-action grinding set clamping device for convenient and safe tightening

- Safety interlock

- Easy 1-button operation with colored graphics display

- New carry handle

- New ergonomic design, heavy grinding sets can be inserted closer to the user´s body and slided into the machine, leading to less strenuous laboratory work especially for high throughput users

Function Principle

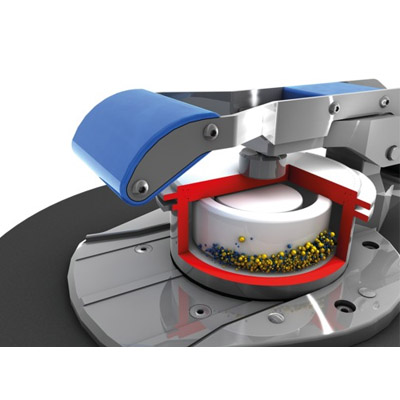

The Vibratory Disc Mill RS 200 comminutes by impact and friction. The grinding set is firmly attached to the vibration plate with a quick-action lever. The plate with the grinding set is subjected to circular horizontal vibrations.

The centrifugal force acting on the grinding rings in the dish results in extreme pressure, impact and frictional forces acting on the sample, producing analytical fineness in 1-3 minutes. The circular vibrations are produced by a frequency controlled 1.5 kW 3-phase motor. A sensor recognizes the presence of agate grinding sets and automatically limits the speed to 700 min-1 to avoid damaging the agate. The cover of the noiseinsulated grinding chamber has a safety interlock and can only be opened when the mill is at a standstill.