Application Examples

Ashes, Cement Clinker, Chemical Products, Coal, Cocoa Nibs, Coke, Drugs, Food, Homeopathic Materials, Nuts, Pharmaceutical Materials, Plant Materials…

Product Advantages

- Dry, wet and cryogenic grinding

- Reproducible results due to adjustable pestle and scraper pressure

- Closed, dust tight grinding chamber with windows

- Easy exchange of mortar and pestle without tools

- Performance display for load control

- Adjustable pestle and scraper pressure

- Wide range of materials for contamination free grinding

- 3 scraper materials (PU, beech wood, PTFE)

- Pestle speed 100 rpm

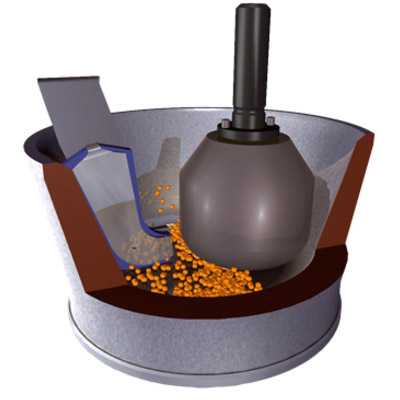

Function Principle

The Mortar Grinder RM 200 comminutes, mixes and triturates by pressure and friction. The function of the scraper is to feed the sample material into the area between the mortar and pestle. This forced feed ensures that the whole of the sample is continuously subjected to the grinding and trituration process and is also intensively mixed.

The grinder pestle is not located in the center of the mortar but is offset; contact with the rotating mortar and the sample causes it to rotate automatically. The necessary grinding pressure is achieved by the weight of the pestle itself combined with the adjustable spring pressure acting on its axis.