The Q2000 offers the ability to process large volumes in individual batches or flow through applications. This model includes a high amplitude (100um), 1.5″ diameter probe and booster. The Q2000 is powerful, durable and customizable. The Q2000 with standard probe is recommended for 5-20L samples. Routine applications include emulsification, cell lysis, degassing, homogenization, solubilizing, deagglomerating and dispersing.

2 additional probe sizes (½” and 1” diameter) are available to accommodate smaller volumes. This enables the Q2000 system to be used for small R&D batches and can be scaled up to production volumes.

For continuous processing applications we offer the Q2000FCE model. This package includes the Sonicator, flocell, flocell probe, booster and chiller.

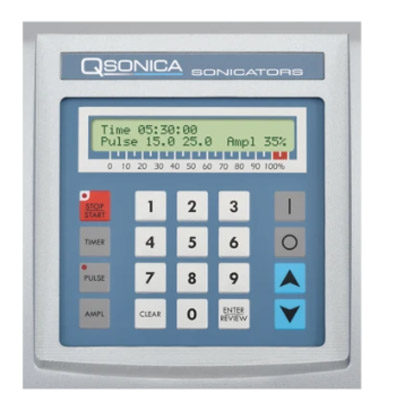

The Q2000 Sonicator allows the user to program processing times and a full range of intensity settings. Processing time can be set from 1 second to 10 hours. A pulsing feature is standard. Pulsing can reduce the amount of heat generated by sonication when processing temperature sensitive samples. A temperature monitoring probe option is also available.

Note: Air cooling of the Converter by a compressed air source is required. The user must provide approximately 10psi (5 cfm) of clean, dry air to prevent overheating of the Sonicator.

Processing volumes are application specific. There are many variables (viscosity, concentration, etc.) that can affect the min/max processing volumes and processing times.

Probes are consumable items which release particulate and require replacement over time. Post processing sample filtration is recommended.

Process liquid tank, pump, valves, tubing and compressed air source are application specific and supplied by the operator.