Application Examples

Alloys, Animal Feed, Bones, Ceramics, Cereals, Chemical Products, Coal, Coke, Drugs, Glass, Grains, Hair, Minerals, Oil Seeds, Ores, Paper, Plant Materials…

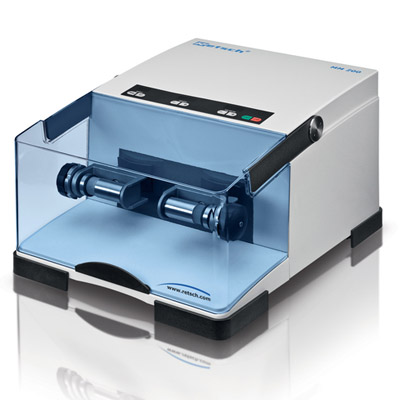

Product Advantages

- Reproducible, efficient grinding, mixing and homogenization in seconds

- Powerful grinding by impact and friction, up to 25 Hz for up to 20 samples per run

- 9 SOPs can be stored

- Wide range of accessories including various jar and ball sizes, adapter racks, grinding tool materials

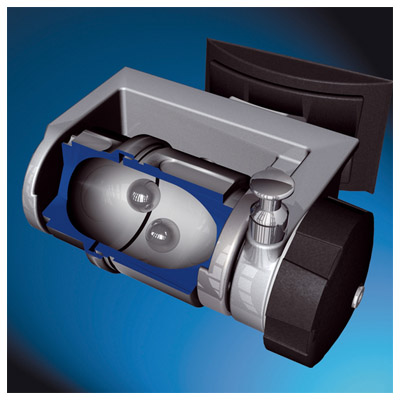

Function Principle

The grinding jars of the MM 200 perform radial oscillations in a horizontal position. The inertia of the grinding balls causes them to impact with high energy on the sample material at the rounded ends of the grinding jars and pulverize it. Also, the movement of the grinding jars combined with the movement of the balls result in the intensive mixing of the sample.

The degree of mixing can be increased even further by using several smaller balls. If several small balls are used (e.g. glass beads) then, for example, biological cells can be disrupted. The large frictional impact effects between the beads ensure effective cell disruption.