Application Examples

Candy, Cereals, Cereal bars, Cheese, Cocoa Nibs, Coated Tablets, Frozen Products, Dietary Supplements, Dried and Fresh Fruit, Feed Pellets, Fish, Ham, Lettuce, Nuts, Meat…

Product Advantages

- Efficient size reduction of up to 700 ml feed quantity due to a powerful 1000 W motor

- Pre- and fine-grinding in one mill: cutting action in regular mode, grinding by impact in reverse mode, pre-grinding in interval mode

- Perfect adaptation to application requirements by variable speed from 2.000 to 10.000 min-1 with an increment of 500 min-1

- Boost function with speed of 14.000 min-1

- 8 SOPs and 4 sequences can be stored

- Touch display with access to MyRETSCH web portal with product and application related information

- Optional gravity lids or volume reduction lids for automatic reduction of the grinding chamber volume

- Grinding jar in plastic, stainless steel and glass available

- All parts which come into contact with the sample material are autoclavable

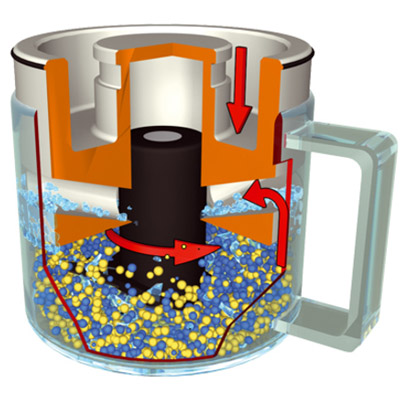

Function Principle

Two sharp, robust blades rotate in the center of the grinding container. Depending on the rotational direction, size reduction is effected with the blunt side (preliminary size reduction) or the sharp side (fine grinding). The knife is indirectly driven by a powerful motor of 1000 W. A pre-selectable speed which is maintained electronically ensures optimum adaptation to individual application requirements as well as reproducible grinding results.