Application Examples

Bauxit, Cement Clinker, Chalk, Chamotte, Coal, Concrete, Construction Waste, Coke, Dental Ceramics, Dried soil Samples, Drilling Cores, Electrotechnical Porcelain, Ferro Alloys, Glass…

Product Advantages

- Excellent crushing performance

- Reproducible results due to accurate gap setting

- Hinged grinding chamber for easy cleaning

- Grinding discs with long working life

- Wide range of materials for contamination free grinding

- Connector for dust extraction

- Can be operated together with Jaw Crusher BB 200

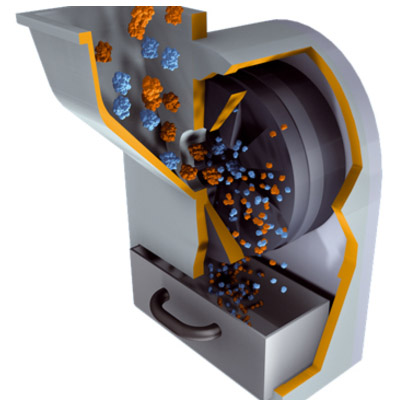

Function Principle

In the DM 200 the feed material enters the dust proof chamber from the filling hopper and is fed centrally between two vertical grinding discs. A moving grinding disc rotates against a fixed one and draws in the feed material. The necessary comminution effects are generated by pressure and frictional forces. The progressively arranged grinding disc meshing first subjects the sample to preliminary crushing; centrifugal force then moves it to the outer regions of the grinding discs where fine comminution takes place. The processed sample exits through the grinding gap and is collected in a receiver. The gap width between the grinding discs is continuously adjustable and can be adjusted during operation in the range between 0.1 and 5 mm; an additional observation window is provided for checking the gap setting.