Application Examples

alloys, basalt, cement clinker, ceramics, chamotte, coal, coke, construction materials, feldspar, glass, granite, minerals, quartz, ores, oxide ceramics, rocks, silicon, slag, …

Product Advantages

- High crushing ratio

- Front door facilitates cleaning

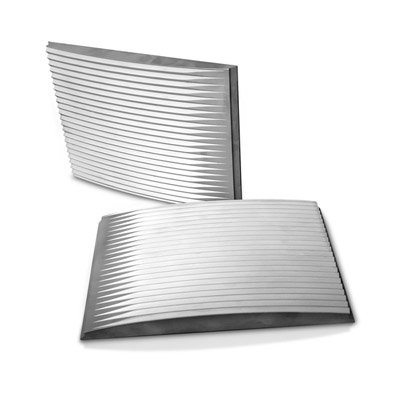

- Infinite/continuous gap width setting

- Overload protection

- Wide range of materials for contamination free grinding

- No-rebound feed hopper, removable

- Sample collector with safety switch

- Collecting receptacle with outlet for continuous operation

- Connector for dust extraction

- Special version with automated sorting of undersize (3 fractions) and oversize (1 fraction) (2 – 6 mm available)

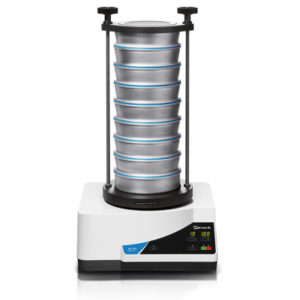

Function Principle

The Jaw Crusher BB 400 is a robust and powerful forced-feed crusher. The feed material passes through the no-rebound hopper and enters the crushing chamber.

Size reduction takes place in the wedge shaped area between the fixed crushing arm and one moved by an eccentric drive shaft. The elliptical motion crushes the sample which is moved towards the crushing gap under gravity.

As soon as the sample is smaller than the discharge gap width, it falls into a removable collector within the jaw crusher. The continuous gap width setting with scale ensures optimum size reduction in accordance with the set gap width.