Application Examples

Cement Clinker, Chemicals, Coal, Coke, Construction Materials, Fillers, Minerals, Ores, Plastics, Sand, Soils, …

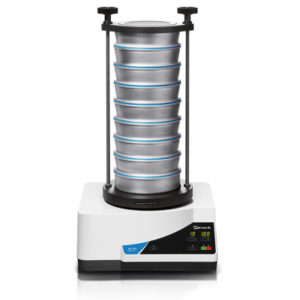

Product Advantages

- Suitable for dry and wet sieving

- Excellent separation efficiency even with short sieving times

- Efficient electromagnetic drive

- 3-D throwing motion which ensures optimum use of the open sieve area and lets the sample move equally over the whole sieving surface

- CET Technology for controlled amplitude even with high loads (up to 25 kg)

- Up to 13 fractions in one sieving operation

- Free digital adjustment of all process parameters (time, amplitude or sieve acceleration, interval)

- Memory for up to 9 SOPs

- Mobile operation panel for comfortable handling

- Optional software EasySieve for control through RS232 serial interface, easy evaluation and documentation of results

- Fulfils all criteria for measuring equipment related to ISO 9001

- Maintenance-free

- Easy operation (clamping), ergonomic design

- Dry and wet sieving in one model

Function Principle

CET technology provides a substantially higher energy input than the technology used in conventional sieve shakers. The AS 450 control achieves the highest amplitude even with maximum load which ensures optimum separation efficiency and high reproducibility.

The electromagnetic drive which lets the sieve stack vibrate continuously transfers its energy in a controlled way to the sieve plate, following the harmonic sinusoidal oscillation of alternating current.

The drive produces a 3D throwing motion that moves the product to be sieved equally over the whole sieving surface. The advantage: high stress capacity, extremely smooth operation and short sieving times with high separation efficiency.