Application Examples

Construction Materials, Ground Corn, Plastics, Sand, Splints

Product Advantages

- Sieving with circular sieving motion according to DIN 53477

- Excellent separation efficiency even with short sieving times

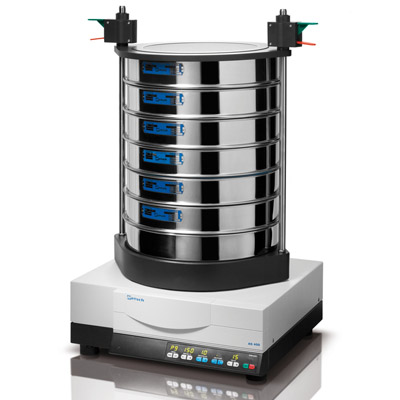

- Sieve stack up to 510 mm height

- Free digital adjustment of all process parameters (time, speed or sieve acceleration, interval)

- Memory for up to 9 SOPs

- Interval operation

- Optional software EasySieve for control through RS232 serial interface, easy evaluation and documentation of results

- Fulfils all criteria for measuring equipment related to ISO 9001

- Maintenance-free

- Easy operation, ergonomic design

Function Principle

The base plate of the AS 400 control performs horizontal circular motions with a radius of 15 mm (according to DIN 53477). The speed of 50 to 300 rpm is electronically controlled. It is continuously adjustable to meet the requirements of the product to be sieved. The actual value of the number of revolutions is digitally displayed. The base plate is driven by a robust, maintenance-free drive motor with a power of 125 Watt. The power is transmitted via an eccentric.