FAQ

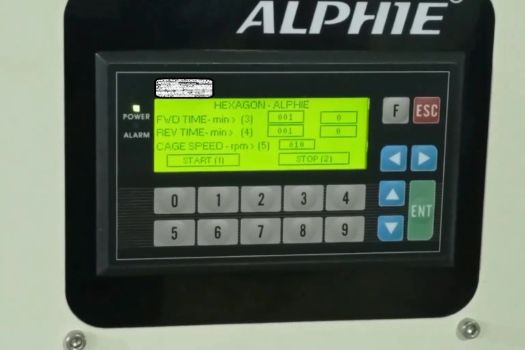

What should be the correct mixing speed?

It is not correct to assume that running at high speed will do fast and better mixing. In many applications, high speed gives adverse mixing results. In normal mixing cases, mixing at 50% of maximum permissible speed should be sufficient to start with.

How much should I fill the material in mixing bottle?

It is always good not to fill more than 70% of bottle total volume. We recommend filling upto 40 – 50%. Mixing time increases exponentially when filled more than 50% of volume.

Is there any preference on mixing direction?

Should i rotate the bottle in clockwise or anti clockwise direction? – There is no preference or rule of mixing direction. You can rotate in any direction suitable to you. However, few of the customers have got better and quicker mixing results when rotated in one direction for half the time and in opposite direction in remaining half batch time.

How long should I mix?

This depends on many variables like % of bottle filled, powder condition etc. However, most applications start getting results in 5 to 15 minutes. Its a myth that more mixing gives better homogeneity.

Is there any shear force acting while mixing?

Alphie mixer runs on the principle of kinematic inversion. So, the bottle does not rotate, but it inverts. So this is theoretically zero shear force mixing.

Can Alphie be used for liquid mixing also?

Yes, Alphie can be used for powder, liquid and suspensions.

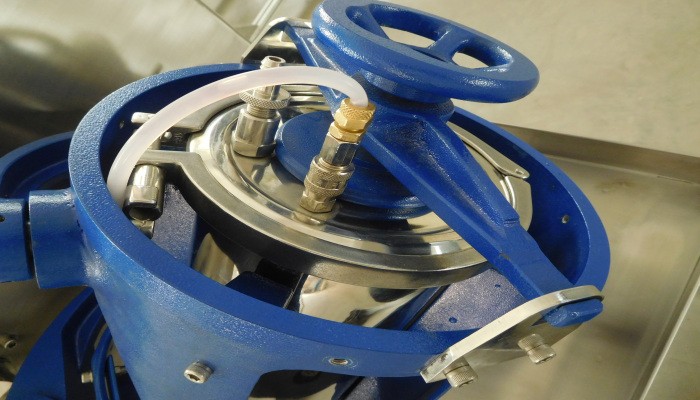

What is the material of mixing container suitable for my application?

Stainless Steel AISI 304 is material suitable for most application. If application is Pharmaceutical or Food; AISI 316L is used. We offer Aluminum / Gun metal containers for explosive powder mixing; Plastic containers are good for other many applications

What is the material of container fixing rubber bands?

The rubber bands are made from Silicone

Do I need to keep spares of rubber bands?

As such, the strings are sturdy enough to live long. We also keep stock of the same in case you need them in emergency.

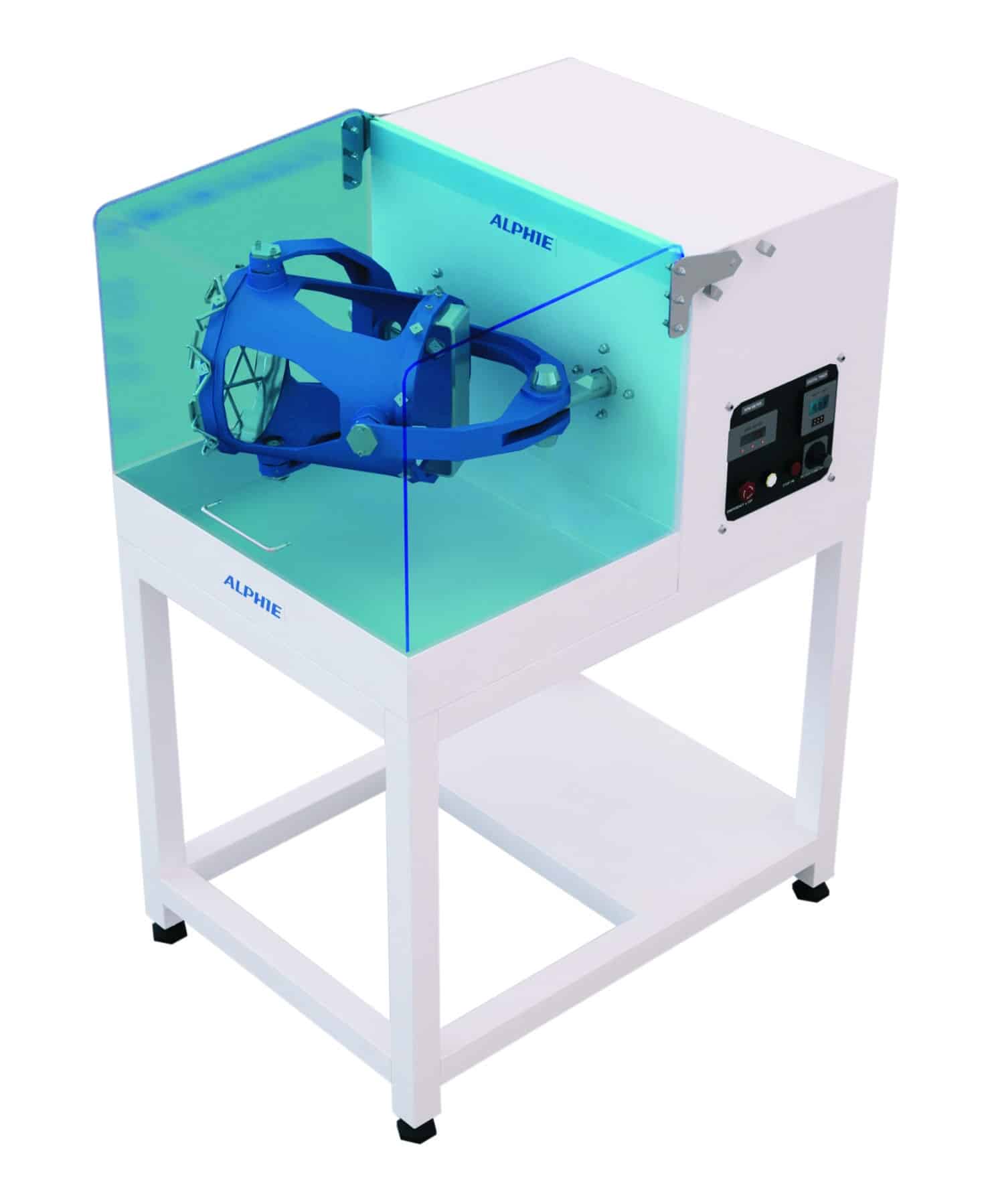

Does Alphie 10 needs grouting or foundation?

No. Alphie 10 is supplied with a table. You just keep on flat surface and level it by levelling pads of mixer.

Can we add balls in mixing container?

Yes, suitable size stainless steel or other material balls can be added. They can be sourced from us also.

Is there any grease / lubrication required in the Alphie, even after one year?

No, Alphie 3 is built with life long lubricated joints. All the bearings are sealed and so does not need any re-lubrication.

How can I learn more about how to use this mixer?

Mixer is supplied with Instruction Manual copy placed inside the tray. Further, a QR code sticker has been placed on the body of mixer near its name plate. Scanning it, will take you to the video of how to use this mixer.

Do you send CE certificate and other documents with the mixer?

Yes, if your mixer is supplied as CE compliance mixer; certificate shall be sent along with the mixer. All mixers are marked with QR code, scanning which you can find all related documents and operating video.

Can you supply mixer complying CE requirement?

Yes, Alphie 10 can be supplied complying the CE requirements.

Can I buy more containers?

Yes, you can plan to buy while purchasing the mixer or can buy later also separately. We keep stock of all size of bottles with us.

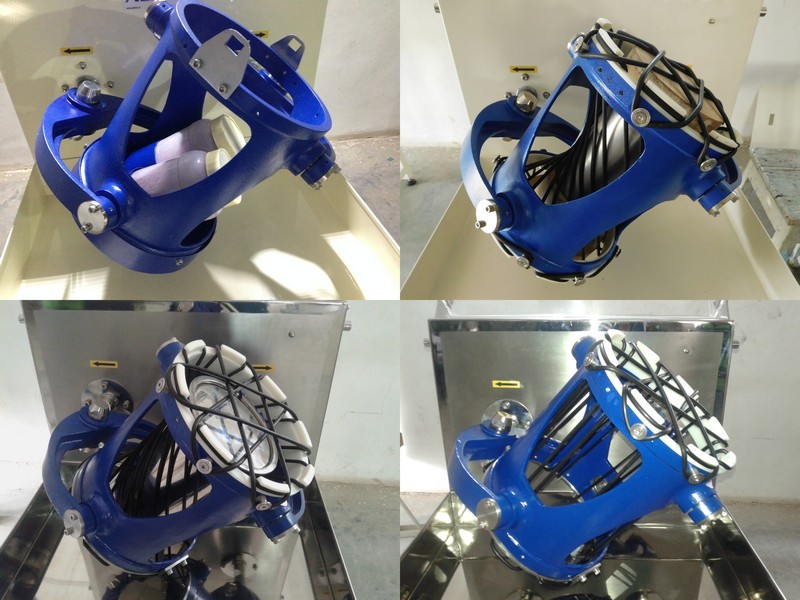

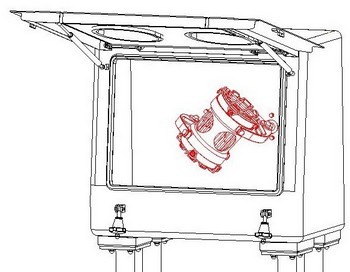

How smaller container can be fitted in the Alphie 10?

Alphie 10 is supplied with Tension Crown – Rubber Clamping Band attachment. It is capable to fit any smaller container of any shape and material. It can fix even a 1 L container also.

How can I scale up my laboratory results for production requirements?

We have developed a program where placing R & D mixer data can generate the speed and time required for larger capacity mixer. As per example, if you have run Alphie 3 for 30 minute and 50 rpm – at what speed and how much time should I run 200 Ltr Mixer.