IMPORTANT FEATURES AND CAPABILITIES

► COOLING. Temperature control must be addressed when using a bead mill cell disrupter for the isolation of proteins, membranes or organelles. The Mini-BeadBeater-96, like all other high-energy, shaking-type bead mill cell disrupters, will heat up a sample from collisional friction of the beads…about 10° for each minute of beadbeating. An important accessory for the MBB-96 is a 48 capacity 2 ml microvial holder and a 2 tube capacity 50 ml tube holder, both machined out of solid aluminum. Cooled beforehand in a deep freezer or with liquid nitrogen, the mass of the aluminum vial holder and its excellent heat transfer properties maintain samples at their initial low temperature during the entire beadbeating run…something that some competitor’s bead mills offering flowing cold air accessories fail to accomplish. The fact is that air is not an efficient media for the transfer and rapid removal of heat. For this same reason, operating a bead mill cell disruptor in a cold room offers little regulation of heat buildup during beadbeating.

But this is not always a concern. Strict temperature control is not a needed when cells or tissue are being disrupted in the presence of DNA or RNA extraction media.

► ”DRY” GRINDING. The Mini-BeadBeater-96 can be used to powder most dried plant and animal tissues and, at liquid nitrogen temperatures, fresh tissues. Exceptions to the rule are woody tissue and some tissues having high lipid or oil content. Most dry grinding is done using steel beads.

When dry- or cryo-grinding plant or animal tissue use our stainless steel microvials with silicone rubber caps, special XXTuff microvials or special Porvair Sciences deep well microplates. Common plastic microvials and deep well plates will break when dry grinding with steel beads.

To the tubes or wells add either one 6.3 mm diameter chrome-steel bead, two 6.3 mm diameter zirconia beads or three 3.2 mm diameter chrome-steel beads. Beadbeat for 5-30 seconds. Note that steel beads can be used in common plastic vials and common deep well microvials for wet grinding, provided that the vial is completely filled with aqueous media and the amount of entrapped air is minimized..

► DEEP-WELL MICROPLATES. When using deep well microplates possible leakage and subsequent cross contamination between wells should be concern. While the entire mat surface area is evenly clamped to the microplate during beadbeating in the Mini-BeadBeater-96, the user must first thoroughly press the mat onto the microplate during the initial sealing process. Rollers and mat presses help in this task (see accessories listed below). The best mats are made of EVA or silicone rubber. Mats made of other rubber-like polymers or adhesive- or heat-bonded films – may not prevent leaking during the intense shaking in the Mini-BeadBeater-96. There is an easy way to check for this concern. Give us a call.

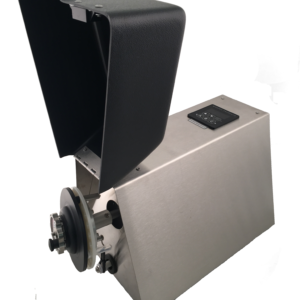

► SPEED CONTROL. The Mini-BeadBeater-96 features digital variable speed control presets between 1400 rpm to 2400 rpm and three programmable time presets. These presets allow for storage of your favorite speed and time settings for easy retrieval.