Powderize

Showing all 22 results

-

Grinding & Milling, Jaw Crushers

BB 300 Jaw Crusher

The Jaw Crusher BB 300 is used for the rapid, effective crushing and pre-crushing of medium-hard, hard, brittle and tough materials. Its variety of materials offered, including heavy-metal free steel and its efficiency and safety makes the BB 300 ideal for sample preparation in laboratories and industrial plants.

For small amounts of sample the Jaw Crusher BB 300 can be used batch-wise; for larger amounts it can be operated continuously. Control of the gap width and zero point adjustment allow for reproducible results. The Belleville spring washer protects the unit from overloads and in conjunction with the central lubrication guarantees a long service life.

SKU: n/a -

Grinding & Milling, Jaw Crushers

BB 400 Jaw Crusher

The Jaw Crusher BB 400 is used for the rapid, effective crushing and pre-crushing of medium-hard, hard, brittle and tough materials. Its variety of materials offered, including heavy-metal free steel, its efficiency and safety makes it ideal for sample preparation in laboratories and industrial plants.

For small amounts of sample the BB 400 is used batch-wise; for larger amounts it can be operated continuously. Control of the gap width and zero point adjustment allow for reproducible results.

Thanks to the modular construction of housing and frame this jaw crusher is suitable for a wide range of applications.

SKU: n/a -

Grinding & Milling, Jaw Crushers

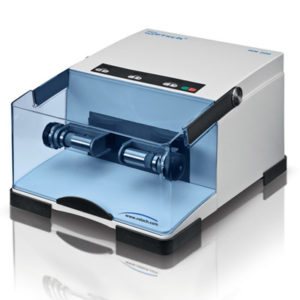

BB 50 Jaw Crusher

The Jaw Crusher BB 50 has been specially designed for sample preparation in the laboratory. It is used for the rapid, effective crushing and pre-crushing of medium-hard, hard, brittle and tough materials.

The space-saving, dust-tight instrument fits on any laboratory bench and is ideally suited to crush small amounts of sample with large feed sizes gently and without loss.

To avoid metallic contamination, the grinding chamber of the jaw crusher is available of ceramic materials. With its digital gap width display and zero point adjustment the jaw crusher BB 50 allows for reproducible results.

SKU: n/a -

Grinding & Milling, Jaw Crushers

BB 500 Jaw Crusher

The Jaw Crusher BB 500 is used for rapid, effective, crushing and pre-crushing of medium-hard, hard, brittle and tough materials. Its variety of materials offered, including heavy-metal free steel, and its efficiency and safety makes the BB 500 ideal for sample preparation in laboratories and industrial plants.

For small amounts of sample the BB 500 is used batch-wise; for larger amounts it can be operated continuously. Control of the gap width and zero-point adjustment allow for reproducible results.

The BB 500 with its steep crushing chamber and powerful drive provides for very effective crushing kinematics.

SKU: n/a -

Grinding & Milling, Jaw Crushers

BB 600 Jaw Crusher

The Jaw Crusher BB 600 is used for rapid, effective, crushing and pre-crushing of medium-hard, hard, brittle and tough materials.

Due to the low installation height (1 m), the BB 600 is ideally suited for continuous operation in automatic installations and sampling stations. Thanks to the compact design of the BB 600 it may replace a jaw crusher in existing installations.

Small sample amounts with large particle sizes can be crushed batch-wise in the Jaw Crusher BB 600.

SKU: n/a -

Disc Mills, Grinding & Milling

DM 400 Disc Mill

The DM 400 is the new comfort model for fine grinding of medium-hard, hard and brittle materials down to 0.05 mm. This model is based on the well-proven DM 200 but offers improved safety features due to the automatic locking of the collecting vessel and grinding chamber, as well as particularly convenient operation thanks to the motor-driven grinding gap adjustment with digital gap display. The clearly structured display shows all grinding parameters.

Thanks to its robust design, the Disc Mill DM 400 can be used under rough conditions in laboratories and pilot plants, as well as online for the quality control of raw materials. The powerful DM 400 requires only a few minutes to achieve the desired grind size.

SKU: n/a -

Grinding & Milling, Knife Mills

Grindomix GM 200 Knife Mill

The knife mill GRINDOMIX GM 200 is the ideal instrument for grinding and homogenizing foods and feeds. It allows to process sample volumes up to 0.7 liters quickly and reproducibly.

With two sharp, robust blades and a powerful 1000 W motor, it is ideal for homogenizing substances with a high water, oil or fat content as well as for grinding dry, soft and medium-hard products. A wide selection of lids and containers allows for adaptation of the mill to individual application requirements. The GRINDOMIX GM 200 meets and exceeds all special laboratory and analytical requirements and is a professional device superior to any commercial household mixer.

SKU: n/a -

Grinding & Milling, Mixer Mills

MM 200 Mixer Mill

The mixer mill MM 200 is a compact versatile benchtop unit, which has been developed specially for dry grinding of small amounts of sample.

It can mix and homogenize powders in only a few seconds. It is also perfectly suitable for the disruption of biological cells as well as for DNA/RNA extraction.You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill for high energy input. The unique combination of high friction and impact results in extremely fine particles within the shortest amount of time.

SKU: n/a -

Cell Disruption, Cryogenic Milling, Grinding & Milling, Mixer Mills

MM 400 Mixer Mill

The mixer mill MM 400 is a compact versatile bench-top unit, which has been developed specially for dry, wet and cryogenic grinding of small amounts of sample.

It can mix and homogenize powders and suspensions in only a few seconds. It is also perfectly suitable for the disruption of biological cells as well as for DNA/RNA and protein extraction. With its high performance and great flexibility the mixer mill MM 400 is a unique product in the market.You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill for high energy input. The unique combination of high friction and impact results in extremely fine particles within the shortest amount of time.

SKU: n/a -

Grinding & Milling, Mixer Mills

MM 500 Mixer Mill

The mixer mill MM 500 is a compact, versatile bench-top unit which has been developed specially for dry, wet and cryogenic grinding of up to 2 x 45 ml sample material within seconds.

With a maximum frequency of 35 Hz, it generates enough energy to produce particles in the nanometer range. The robust high-performance drive makes the mill suitable for long-term grinding processes up to 99 hours. Hence, the MM 500 is the first mixer mill in the market to provide a real alternative to grinding in a planetary ball mill – with more comfortable handling and less warming effects.

SKU: n/a -

Grinding & Milling, Planetary Ball Mills

PM 400 Planetary Ball Mill

Planetary Ball Mills are used wherever the highest degree of fineness is required. Apart from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying processes. The extremely high centrifugal forces of planetary ball mills result in very high pulverization energy and therefore short grinding times.

The PM 400 is a robust floor model with 4 grinding stations.

You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill for high energy input. The unique combination of high friction and impact results in extremely fine particles within the shortest amount of time.

SKU: n/a -

Cryogenic Milling, Grinding & Milling, Mortar Grinders

RM 200 Mortar Grinder

The Mortar Grinder RM 200 can mix and homogenize powders, suspension and pastes, even for samples with high viscosity. The RM 200 is suitable for the proper and reproducible sample preparation to analytical fineness.

The sample grinder substitutes cumbersome hand mortars by a high performance drive with electronic control. The grinding set can be cooled and heated and is very easy to clean. Grinding sets of various material qualities are available which can be exchanged easily for optimum adaptation to various grinding tasks.

SKU: n/a -

Disc Mills, Grinding & Milling

RS 200 Vibratory Disc Mill

The Vibratory Disc Mill RS 200 is suitable for the extremely quick, loss-free and reproducible grinding of medium-hard, brittle and fibrous materials to analytical fineness. The instrument runs steadily and smoothly, even with heavy grinding sets, at maximum speed thanks to the new Stabilized-Plane-Drive.

With its robust design, the RS 200 has proven to be ideal for use in the building materials sector (cement), in geology, mineralogy, metallurgy and in power plants. Due to the high end fineness and speed the RS 200 is the perfect mill when it comes to preparing samples for spectral analysis.SKU: n/a -

Disc Mills, Grinding & Milling

RS 300 Vibratory Disc Mill

The Vibratory Disc Mill RS 300 is suitable for the extremely quick, loss-free and reproducible grinding of medium-hard, brittle and fibrous materials to analytical fineness. It is possible to process 1, 2, 3 or 4 samples simultaneously. Thanks to the robust universal drive shaft, which sets the grinding jar into a 3-D motion, this mill accepts grinding set weights of up to 30 kg. The closed grinding system guarantees complete processing of the sample.

Just like the RS 200, the RS 300 with its robust design has proven to be ideally suitable for applications in geology, mineralogy, metallurgy, as well as in the building materials sector (cement) and in power plants.

Due to the high end fineness and speed, the Vibratory Disc Mills are the perfect choice when it comes to preparing samples for spectral analysis.

SKU: n/a -

Grinding & Milling, Rotor Mills

SK 300 Cross Beater Mill

The Cross Beater Mill SK 300 is suitable for coarse and fine size reduction, either in batches or continuously. It can process medium-hard and brittle materials and is easy to operate.

With its adjustable speed of 2,000 to 4,000 rpm the SK 300 is intended for universal use: from sample preparation in laboratories up to preparing sample batches in pilot plants or production facilities.

SKU: n/a -

Cutting Mills, Grinding & Milling

SM 100 Cutting Mill

Cutting mills are suitable for the grinding of soft, medium-hard, elastic, fibrous, and heterogeneous mixes of products.

The SM 100 is the budget-priced basic model among the cutting mills. With its strong 1.5 kW drive and 1,500 rpm rotor speed the mill is particularly suitable for routine applications. Cleaning is made particularly easy.

In combination with the wide choice of bottom sieves, hoppers and collecting vessels, the mill can be easily adapted to varying application requirements. The SM 100 can be bench-mounted; alternatively a convenient base frame on wheels is available.

SKU: n/a -

Grinding & Milling, Rotor Mills

SR 300 Rotor Beater Mill

The Rotor Beater Mill SR 300 is suitable for coarse and fine size reduction, either in batches or continuously. It can process dry, soft, medium-hard, organic and inorganic substances.

With its adjustable speed of 3,000 to 10,000 rpm the rotor beater mill SR 300 is intended for universal use: from sample preparation in laboratories up to preparing sample batches in pilot plants or production facilities. The grinding chamber, the feed hopper and the material inlet are completely made from high quality stainless steel.

SKU: n/a -

Grinding & Milling, Rotor Mills

TWISTER Cyclone Mill

The cyclone mill TWISTER is specially designed for the processing of foods and feeds for subsequent NIR analysis. The optimized form of rotor and grinding chamber generates an air jet which carries the ground sample through the integrated cyclone into the sample bottle. The air jet prevents the material from heating up, thus preserving the moisture content.

The provided sieves guarantee an optimum particle size distribution so that it is not necessary to recalibrate the NIR spectrometer. The rotor speed can be adjusted in 3 steps allowing for perfect adaptation to the sample requirements. Cleaning the mill is quick and easy as the air jet effects a complete discharge of the material from the grinding chamber.

This new cyclone mill in proven quality optimizes the reproducible sample preparation to NIR analysis thus allowing for meaningful and reliable analysis results.

SKU: n/a -

Grinding & Milling, Rotor Mills

ZM 200 Ultra Centrifugal Mill

The Ultra Centrifugal Mill ZM 200 is a high speed rotor mill with unmatched performance. It is used for the rapid size reduction of soft to medium-hard and fibrous materials.

Because of the efficient size reduction technique the ZM 200 ensures the gentle preparation of analytical samples in a very short time. The comprehensive range of accessories including a large variety of ring sieves and rotors as well as collection systems makes the Ultra Centrifugal Mill a versatile instrument that can be easily adapted to varying applications. The optional Vibratory Feeder is load-controlled via an interface and ensures a uniform grind at maximum output rate. When using a cyclone, the sample material is additionally cooled by the air stream and more rapidly discharged from the grinding chamber via the cassette pan with outlet. This effect can be increased by connecting a vacuum cleaner.

With thousands of installations, the ZM 200 has become a standard for food and feeds, for the chemical industry as well as for agricultural testing.

SKU: n/a