Advantages of the Alphie Mixer

The best possible homogeneity to analyze representative samples or guarantee distribution coefficients. Compounds of different densities or sizes will mix completely and efficiently. Whether unequal concentrations, never the fear of the lump formation when adding liquid to your powders.

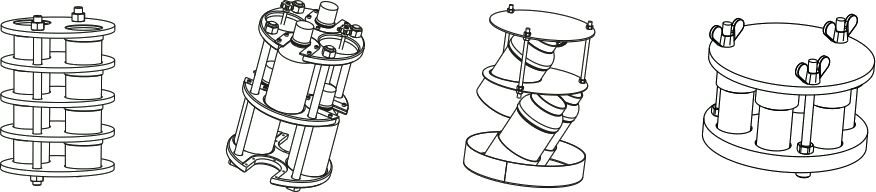

Adjustable Holder for Multiple Size Containers

Available Adapters for Multiple Containers

Alphie Removable Container Model Specifications

Specifications | Alphie 3 | Alphie 10 | Alphie 20 | Alphie 35 | Alphie 50 |

Capacity (Ltr) | 2.5 | 10 | 20 | 35 | 50 |

Effective Capacity @ 80% (Ltr) | 2 | 8 | 16 | 28 | 40 |

Max Mixing Mass (Kg) | 5 | 15 | 30 | 40 / 60 | 60 / 90 |

Motor Powder | 0.3 hp | 0.5 hp | 1.0 hp | 1.0 / 1.5 hp | 3.0 / 5.0 hp |

Container Revolution (rpm) | 10-80 | 10-70 | 10-50 | 10-40 | 10-40 |

Max Container Size (mm) | Dia 115 x 275 Long | Dia 220 x 350 Long | Dia 265 x 410 Long | Dia 305 x 535 Long | Dia 350 x 550 Long |

Machine Weight (Kg) | 70 | 120 | 220 | 390 | 500 |

Overall Dimensions (mm) | 550 x 700 x 550 | 700 x 930 x 1250 | 1030 x 1200 x 1000 | 1200 x 1400 x 1500 | 1400 x 1900 x 1000 |

Power Supply | 110 V | 110 V | 110 V | Offered in either single phase 110 V, or 3 phase 220 V | 3 phase, 220 V |

Alphie Fixed Drum 3D Powder Mixers for Production

Alphie Fixed Container Mixer Specifications

Specifications | Alphie 100 | Alphie 200 | Alphie 400 | Alphie 600 | Alphie 800 | Alphie 1000 | Alphie 1500 |

Capacity (L) | 100 | 200 | 400 | 600 | 800 | 1000 | 1500 |

* Effective Capacity @ 80% (L) | 80 | 160 | 320 | 480 | 640 | 800 | 1200 |

Mixing Capacity (kg) | 80 | 100 | 200 | 300 | 400 | 500 | 750 |

Motor Power | 2.2 hp | 3.0 hp | 4.0 hp | 5.5 hp | 7.5 hp | 7.5 hp | 11.0 hp |

Container Revolution (rpm) | 30 | 25 | 25 | 25 | 20 | 20 | 20 |

Machine Dimension LxWxH | 1350 x 1500 x 1550 | 1800 x 1600 x 1725 | 2250 x 1900 x 1750 | 2400 x 2150 x 2100 | 2600 x 2500 x 2600 | 2800 x 2600 x 2800 | 3400 x 3200 x 3100 |

Machine Weight (kg) | 400 | 700 | 1100 | 1500 | 2300 | 2800 | 4400 |

-

Powder Mixing

Alphie 2 Liter Manual 3D Tumble Mixer

The motion of Alphie mixer is based on the kinematic inversion principle. The unusual, three-dimensional mixing motion quickly and efficiently produces a homogeneous substance regardless of specific weight of the substances being mixed. This makes it an ideal powder blender or liquid mixer.

Manual Alphie Mixer brings same technology power – generating rhythmic and pulsating movement controlled naturally by hand. Added with the mobility!

Typical applications

It is ideal for use in R & D laboratories, educational institutes, small batch production industry, food/nutrition, pharmaceuticals, metal powder, resin and plastic powder, restaurants, bars and kitchens, bakery, spices, concentrates and many more applications

SKU: n/a -

Powder Mixing

Alphie 50 Liter 3D Powder Mixer

Alphie 3D mixers are ideal for homogeneous mixing of powder – be it with different bulk density or different proportion of mixing or different shape and particle size. The best part is, separate and detachable mixing drums / containers / bins are loaded inside the mixing cage, meaning no cross contamination and exposure to work environment.

Our 50 liter model uses identical principals as the smaller R & D scale models. It means the machine shall rotate in similar three dimensional motion and shall yield same results.

Typical applications

It is ideal for use in medium to large batch production industries like food / nutrition, pharmaceuticals, metal powder, resin and plastic powder, bakery, spices, concentrates, nuclear fuel and many more applications.

SKU: n/a -

Powder Mixing

Alphie 20 Liter 3D Powder Mixer

Alphie 3D mixers are ideal for homogeneous mixing of powder – be it with different bulk density or different proportion of mixing or different shape and particle size. The best part is, separate and detachable mixing drums / containers / bins are loaded inside the mixing cage, meaning no cross contamination and exposure to work environment.

Our 20 liter model uses identical principals as the smaller R & D scale models. It means the machine shall rotate in similar three dimensional motion and shall yield same results.

Typical applications

It is ideal for use in medium to large batch production industries like food / nutrition, pharmaceuticals, metal powder, resin and plastic powder, bakery, spices, concentrates, nuclear fuel and many more applications.

Please see this video showing how to use smaller containers down to 2.0 liters.

SKU: n/a -

Powder Mixing

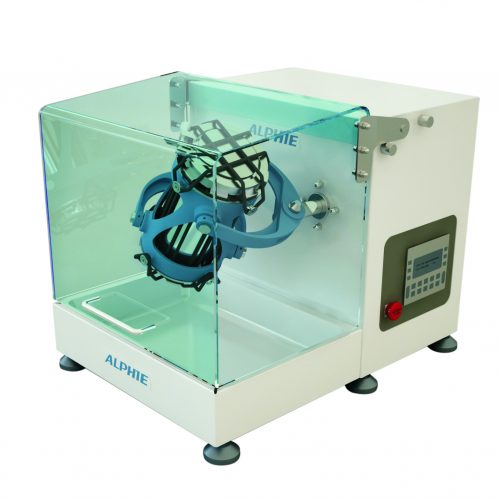

Alphie 10 Liter 3D Powder Mixer

The Alphie 10 liter mixer is ideal for homogeneous mixing of powder – be it with different bulk density or different proportion of mixing or different shape and particle size. The best part is, separate and detachable mixing drum / container / bin is loaded inside the mixing cage, meaning no cross contamination and exposure to work environment.

It is perfect for use in R & D laboratories, educational institutes, small batch production industry, food / nutrition, pharmaceuticals, metal powder, resin and plastic powder, Nano powder, IOL Polishing, Diamond tool powder, bakery, spices, concentrates and many more applications.

SKU: n/a -

Powder Mixing

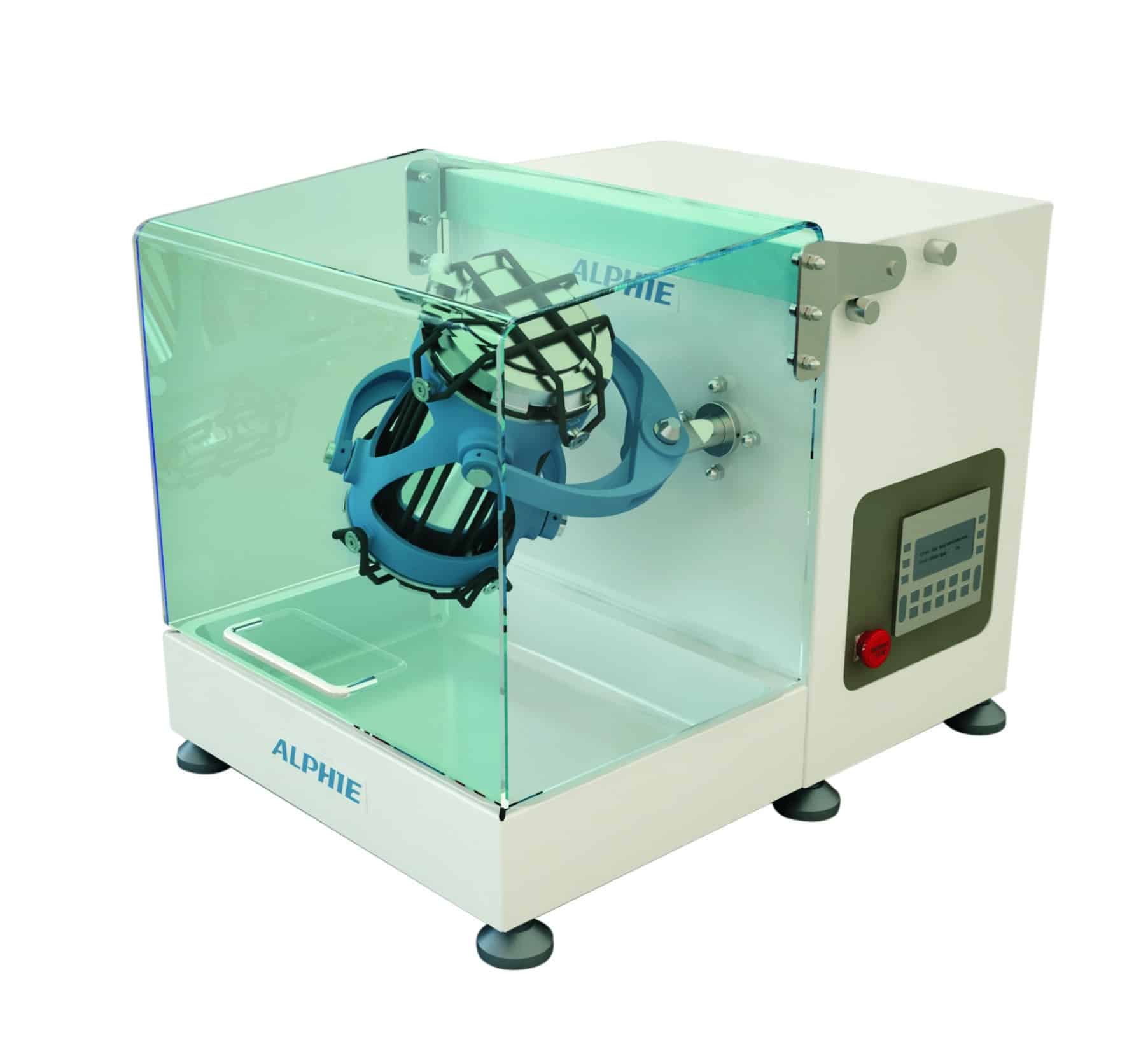

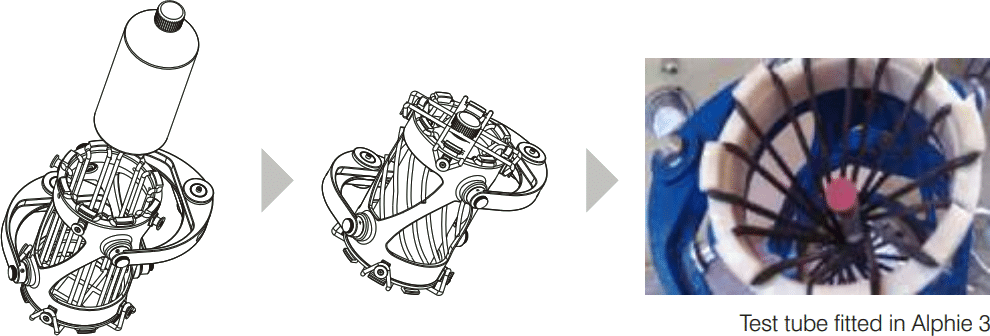

Alphie 3- 2.5 Liter 3D Powder Mixer

Alphie mixer are ideal for homogeneous mixing of powder – be it with different bulk density or different proportion of mixing or different shape and particle size. The best part is, separate and detachable mixing drum / container / bin is loaded inside the mixing cage, meaning no cross contamination and exposure to work environment.

SKU: n/a -

Powder Mixing

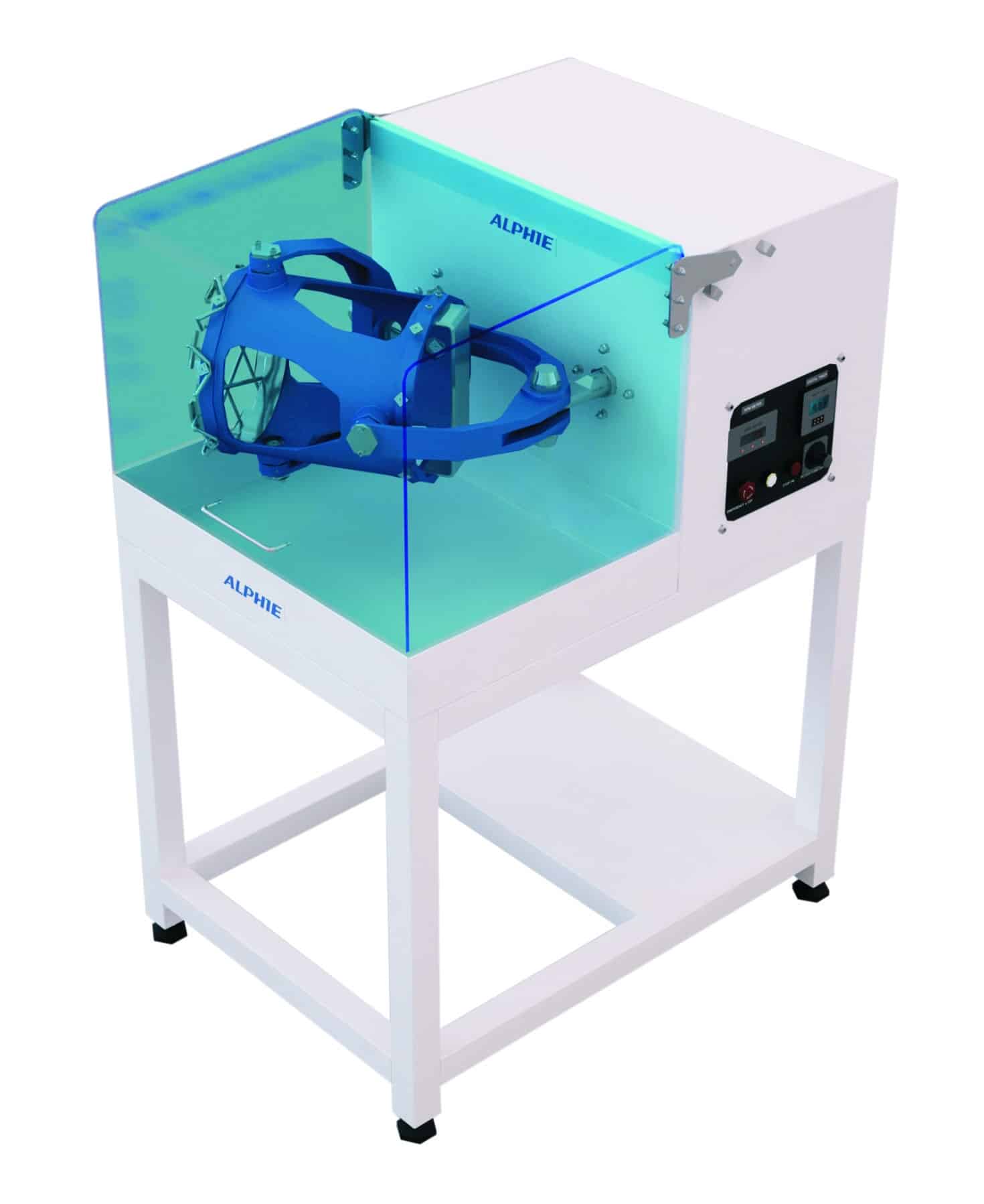

Alphie 35 Liter 3D Powder Mixer

Alphie 3D mixers are ideal for homogeneous mixing of powder – be it with different bulk density or different proportion of mixing or different shape and particle size. The best part is, separate and detachable mixing drums / containers / bins are loaded inside the mixing cage, meaning no cross contamination and exposure to work environment.

Our 35 liter model uses identical principals as the smaller R & D scale models. It means the machine shall rotate in similar three dimensional motion and shall yield same results.

Typical applications

It is ideal for use in medium to large batch production industries like food / nutrition, pharmaceuticals, metal powder, resin and plastic powder, bakery, spices, concentrates, nuclear fuel and many more applications.

SKU: n/a